Popular Soundproofing Materials for Insulation Installations

Discover the most sought-after soundproof insulation products that deliver reliable performance and easy installation.

Soundproof insulation installation is an essential aspect of creating quieter, more private indoor environments. It involves selecting the right materials and products to reduce noise transmission between rooms or from external sources. Proper installation can significantly enhance comfort in residential, commercial, and industrial spaces, making it a popular choice for those seeking to improve acoustic performance. When considering soundproofing solutions, it is important to understand the various product options available, their specific applications, and how they can be integrated into existing structures.

Soundproof insulation installation is an essential aspect of creating quieter, more private indoor environments. It involves selecting the right materials and products to reduce noise transmission between rooms or from external sources. Proper installation can significantly enhance comfort in residential, commercial, and industrial spaces, making it a popular choice for those seeking to improve acoustic performance. When considering soundproofing solutions, it is important to understand the various product options available, their specific applications, and how they can be integrated into existing structures.

Top Overall Option

Acoustic Insulation Panels

Acoustic insulation panels are versatile and effective for reducing sound transmission in various settings. They come in a range of densities and sizes, allowing for tailored solutions in walls, ceilings, and floors. Easy to install with adhesive or mechanical fasteners, these panels can be integrated into both new constructions and retrofit projects. Their ability to absorb sound waves makes them a popular choice for improving acoustic comfort in residential and commercial spaces.

Types of Products For Soundproof Insulation Installations

Mineral Wool Batts

Flexible and easy to install, mineral wool batts provide sound absorption and thermal insulation, suitable for walls and ceilings.

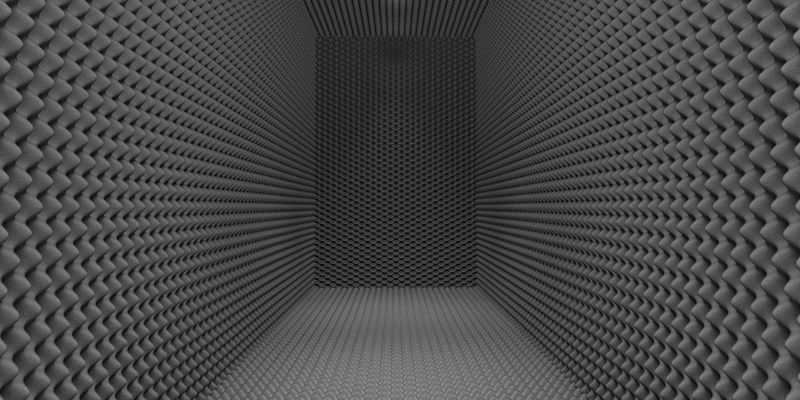

Foam Acoustic Panels

Lightweight and customizable, foam acoustic panels help dampen sound reflections and improve room acoustics.

Mass Loaded Vinyl

A dense, flexible material used to block sound transmission through walls and floors when layered with other insulation.

Resilient Channel Systems

Metal channels that decouple drywall from framing, reducing sound transmission between rooms.

Acoustic Sealants

Specialized sealants used to close gaps and cracks around insulation and panels to improve soundproofing effectiveness.

Soundproof Drywall

Gypsum boards designed with additional mass and damping properties to enhance sound isolation.

Fiberglass Insulation

Commonly used in walls and attics, fiberglass provides sound absorption and thermal insulation.

Acoustic Underlayment

Installed beneath flooring materials to minimize impact noise and airborne sound transmission.

Soundproof Door Sweeps

Seals gaps at the bottom of doors to prevent sound leaks and improve room privacy.

Decoupling Mounts

Vibration isolators that reduce sound transmission through mechanical connections and fixtures.

Acoustic Ceiling Tiles

Suspended ceiling tiles designed to absorb sound and improve room acoustics.

Soundproof Window Inserts

Removable or permanent inserts that reduce noise infiltration through windows.

Damping Compounds

Viscous materials applied between layers of drywall to dampen vibrations and sound transmission.

Acoustic Barrier Paint

Specialized paint formulations that add mass and help reduce sound penetration through walls.

Popular Choices

Widely used for soundproofing and insulation in various building projects, valued for ease of installation.

Commonly selected for their aesthetic appeal and effectiveness in controlling echoes and reverberations.

Popular for its high-density properties and ability to block sound when layered with other materials.

Favored for their ability to decouple drywall and improve sound isolation between spaces.

Often used in conjunction with other soundproofing products to seal gaps and improve overall performance.

Selected for retrofit projects and new constructions aiming for enhanced sound insulation.

A common choice for insulating walls and ceilings, offering both thermal and acoustic benefits.

Popular for reducing impact noise in multi-story buildings and apartments.

Frequently installed to block sound leaks at door thresholds in various settings.

Chosen for reducing vibrations and noise transfer through mechanical fixtures.

Commonly used in commercial spaces to improve room acoustics and reduce noise levels.

Increasingly popular for their ease of installation and effectiveness in noise reduction.

Often applied in drywall assembly to dampen vibrations and improve soundproofing.

A quick solution for adding an extra layer of sound attenuation to existing walls.

Materials designed for soundproof insulation often focus on absorbing sound waves, blocking noise paths, or a combination of both. These products can be used in walls, ceilings, floors, and even door or window assemblies. The effectiveness of soundproofing depends on proper installation, the type of material used, and the specific noise reduction goals. Some products are designed to be added during construction, while others can be retrofitted into existing spaces with relative ease.

Choosing the right soundproof insulation products requires careful consideration of factors such as material density, ease of installation, compatibility with existing structures, and cost. It is also beneficial to consider the sound frequency range you aim to mitigate, as some products perform better at blocking high-frequency noise while others excel at reducing low-frequency sounds. Consulting product specifications and installation guidelines can help ensure optimal performance and long-lasting results in your soundproofing projects.

Key Buying Considerations

- Determine the primary noise source and frequency range to select appropriate materials.

- Assess the compatibility of insulation products with existing structures and building codes.

- Consider the ease of installation and whether professional help is needed.

- Evaluate the density and thickness of materials for their sound blocking or absorption capabilities.

- Check for fire safety ratings and compliance with local regulations.

- Think about the overall project scope, including whether products are suitable for retrofit or new construction.

- Review product dimensions and whether they fit the intended space without modification.

- Analyze cost versus performance to find a balance that meets your needs and budget.

- Look for products with good adhesion and durability for long-term effectiveness.

- Consider aesthetic factors if visible surfaces will be exposed or integrated into interior design.

- Research user reviews and expert opinions for insights into real-world performance.

- Identify if products need additional sealing or accessories for optimal results.

- Determine if the insulation materials are compatible with other soundproofing components being used.

- Evaluate environmental factors such as moisture or temperature exposure that could impact performance.

- Ensure availability of technical support or customer service from suppliers.